Description

Our lithium batteries, crafted by a leading manufacturer, are ideal for wholesale buyers and OEM battery customers. They offer high performance, long – life, and are tailored to various industrial needs.

Key Features

Our lithium batteries are known for their high energy density and low self – discharge rate. They can operate efficiently in a wide range of temperatures, making them suitable for diverse environments. For OEM customers, we can customize the battery’s size, capacity, and output voltage. Our 48V 460Ah LiFePO4 Forklift Battery is a prime example of our innovation, designed to provide long – lasting power for heavy – duty forklifts.

Product Description

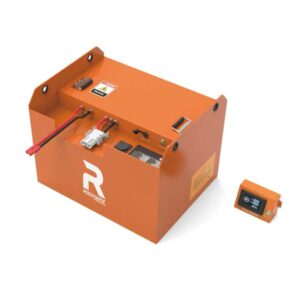

As a lithium battery manufacturer, we use the latest technology and high – quality materials to produce batteries. Our production process adheres to strict quality control standards. The batteries are composed of advanced lithium cells, a reliable battery management system (BMS), and a rugged outer casing. This combination ensures safety, durability, and optimal performance.

A 36V 250Ah LiFePO4 forklift battery from Redway ESS provides long-lasting, reliable power by combining advanced lithium iron phosphate chemistry with intelligent battery management. Offering over 4000 deep cycles at 80% depth of discharge, high continuous and peak discharge currents, and robust safety features, it ensures efficient operation and reduced downtime for industrial forklifts.

What are the key features of the 36V 250Ah LiFePO4 forklift battery from Redway ESS?

Redway ESS’s 36V 250Ah battery delivers a nominal voltage of 38.4V and a capacity of 250Ah, providing approximately 9.6 kWh of energy. It supports continuous discharge currents of 240A and peak discharge currents up to 720A for short bursts. The battery is housed in a durable metal casing with IP65 protection and integrates a smart BMS with communication options such as RS485, CAN bus, and 4G connectivity for real-time monitoring.

How does the Battery Management System (BMS) enhance safety and performance?

The BMS continuously monitors cell voltages, current, temperature, and state of charge to prevent overcharge, over-discharge, short circuits, and overheating. It balances cell voltages to maximize usable capacity and extend battery life. Advanced communication protocols enable remote diagnostics and predictive maintenance, reducing operational risks.

Why is LiFePO4 chemistry preferred for forklift batteries?

LiFePO4 chemistry offers superior thermal stability, long cycle life exceeding 4000 cycles at 80% depth of discharge, and high energy density. It maintains stable voltage output, resists thermal runaway, and is environmentally friendly. Compared to lead-acid batteries, it is lighter, faster charging, and requires less maintenance.

What are the typical applications for a 36V 250Ah LiFePO4 battery?

Ideal for electric forklifts, warehouse vehicles, automated guided vehicles (AGVs), and other industrial equipment requiring reliable, high-capacity power with extended runtime and fast recharge capabilities.

How does the battery’s design contribute to durability and reliability?

The battery’s robust metal casing with IP65 rating protects against dust and water ingress, ensuring durability in harsh industrial environments. Its compact form factor and optimized weight (~250 kg) allow easy installation and integration into various forklift models.

What are the charging and discharging specifications?

The battery uses a CC/CV charging profile with a maximum charge voltage of 43.2V and supports continuous charge currents up to 100A. It delivers continuous discharge currents of 240A and peak discharge currents of 720A for 3 seconds. Operating temperature ranges from -20°C to 60°C for discharge and 0°C to 45°C for charging.

Charging and Discharging Specifications

| Specification | Value |

|---|---|

| Nominal Voltage | 38.4V |

| Nominal Capacity | 250Ah |

| Nominal Energy | 9.6 kWh |

| Max Continuous Charge | 100A |

| Max Continuous Discharge | 240A |

| Peak Discharge Current | 720A (3 seconds) |

| Max Charge Voltage | 43.2V |

| Cycle Life | >4000 cycles @ 80% DoD |

| Operating Temperature | Charge: 0°C to 45°C |

| Discharge: -20°C to 60°C | |

| Protection Rating | IP65 |

How do temperature and environmental factors affect battery performance?

The battery performs reliably within a wide temperature range and features IP65 protection to withstand dust and water ingress, making it suitable for demanding industrial environments. The BMS actively manages thermal conditions to prevent damage and maintain optimal performance.

How can multiple 36V 250Ah batteries be connected for larger systems?

Batteries can be connected in series to increase voltage or in parallel to increase capacity. Redway ESS provides expert guidance to ensure proper BMS synchronization and system design, optimizing balanced charging and discharging.

What maintenance practices maximize battery life?

Maintenance includes regular inspection of terminals and connectors, adherence to charging protocols, avoiding deep discharges, and monitoring via BMS. Redway ESS offers firmware updates and technical support to maintain peak battery health.

How does Redway ESS support customers with their LiFePO4 forklift batteries?

Redway ESS offers customized 36V 250Ah LiFePO4 forklift batteries with advanced BMS, rugged design, and smart connectivity options like Bluetooth and CAN bus. Their expert team ensures seamless integration, reliable operation, and comprehensive after-sales service tailored to client needs.